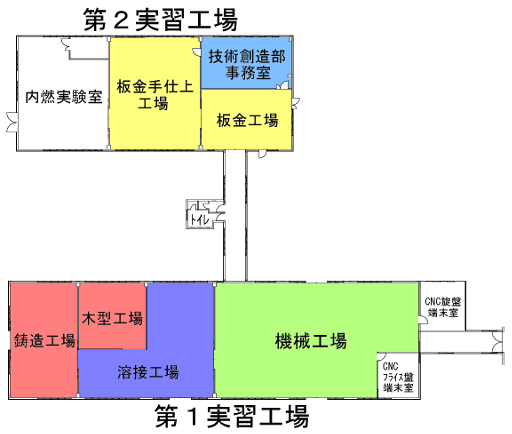

Practical training factory

Practices include general-purpose machine tools, numerically controlled machine tools, welding, sheet metal, casting and finishing, and other electronic machine and mechatronic equipment. These facilities are used for practical training and experiments in the main course, other graduation research, and special research in the major.

Facility/Equipment Overview

Machine factory

- 1 CNC lathe (Okuma: LB3000EX Ⅱ L C500)

-

This is a machine that can perform multiple precision machining of cylindrical and cylindrical materials such as metals into the same shape by computer control.

Specifications Maximum machining diameter: φ410 [mm]

Maximum machining length: 500 [mm]

Spindle rotation speed: 45 ~ 5,000 [min-1]

Spindle through hole Diameter: φ80 [mm]

Number of tools to be installed: 12

Anti-crash system (collision prevention function) is installed

- 1 horizontal multi-task machine (Okuma: MULTUS B200Ⅱ C specification)

-

A NC lathe with a machining center function that enables complex shape machining of cylindrical and cylindrical materials such as metal.

Specifications Maximum machining diameter: φ600 [mm]

Maximum machining length: 550 [mm]

Spindle rotation speed: 50 to 6,000 [min-1]

Travel distance ( XxYxZ): 500x160x600 [mm]

Rapid feed speed (XxYxZ): 40,000x40,000x26,000 [mm/min]

Spindle through hole diameter: φ60 [mm]

Number of tool mounting: 20 >Equipped with anti-crash system (collision prevention function)

- One 5-axis control vertical machining center (D300, made by Makino Milling Machine)

-

This is a precision machine tool that manufactures parts of various types such as optics, medical care, semiconductors, aircraft, molds, etc.

Specifications Travel distance (XxYxZ): 300x500x350 [mm]

Travel distance A-axis/C-axis: ± 120 ° (240 °), continuous rotation 360 °

Maximum work size: φ450x270 [mm] (conditional )

Spindle speed 50 ~ 15,000 [min-1]

Feed speed X/Y/Z: 60,000 [mm/min]

Feed speed A/C: 45,000 ・54,000 [°/min]

- 1 CNC milling machine (Enshu NBV-450)

-

This is a machine tool that can process materials into a three-dimensional shape. Processing is performed by computer control.

Specifications Travel distance (XxYxZ): 920x450x510 [mm]

Work surface dimensions (XxY): 1300x420 [mm]

Table dimensions (XxY): 1500x520 [mm]

Spindle speed: 10 to 4,000 [min-1]

Retraction Drive Acceleration Spindle: Up to 24,000 [min-1]

Return Spindle: Approx. 37,000-50,000 [min>-1]

Cutting feed rate X/Y/Z: 1 ~ 4,000 [mm/min]

Rapid feed rate X/Y: 10,000 [mm/min]

Rapid feed rate Z: 6,000 [mm/min]

Minimum setting unit: 0.001 [mm]

- Three ordinary lathes (Takizawa Iron & Steel Works: TAL-460)

-

A machine tool that rotates a material and performs cutting with a tool called a fixed tool. Because the material rotates, the workpiece always becomes symmetrical with respect to the axis of rotation (cylinder, cone, dish, etc.).

Specifications Maximum machining diameter: 460 [mm]

Maximum machining length: 800 [mm]

Spindle speed: 25 ~ 1500 [min-1]

Number of tool attachments : Up to 4

- Two ordinary lathes (TSL-550, Takizawa Steel Works)

-

Specifications Maximum machining diameter: 360 [mm]

Maximum machining length: 550 [mm]

Spindle speed: 83 ~ 1800 [min-1]

Number of tool attachments : Up to 4

- 2 milling machines (Hitachi Via Engineering: 2MW-V)

-

It is a machine that performs plane processing and groove processing on materials. Operation is performed with a manual handle.

Specifications Travel distance (XxYxZ): 710x300x400 [mm]

Spindle speed: 50 ~ 1500 [min-1]

Feed rate X/Y: 15 ~ 1200 [mm/min]

Feed speed Z: 8 ~ 600 [mm/min]

- One milling machine (Iwashita: 2VB)

-

Specifications Travel distance (XxYxZ): 700x300x400 [mm]

Spindle speed: 30 ~ 1800 [min-1]

Feed speed X/Y: 15 ~ 1800 [mm/min]

Feed speed Z: 8 to 800 [mm/min]

- Cylindrical grinder (made by Sigir: GPS-20) 1 unit

-

It is a machine for finishing the outer and inner surfaces of materials, such as the final finishing of cylindrical parts. Used for machining shafts that incorporate bearings.

Specifications Swing on table: φ200 [mm]

Maximum processing diameter: φ200 [mm]

Maximum processing weight: 20 [kg]

Distance between centers: 250 [mm]

Taper: MT No.3

- One surface grinder (Okamoto: GRIND-X PSG52DX)

-

This machine is used to finish the surface of a material. A good parallel surface can be obtained.

Specifications Table working surface size (length x width): 550x200 [mm]

Distance between table and grindstone: 47.5-397.5 [mm]

Work piece allowable mass: 200 [kg]

Used grindstone (Outer diameter x width x inner diameter): φ205 x 19 x φ50.8 [mm]

Wheel speed: 3,000 [min-1]

Precision vise for non-magnetic material (width x height x Length): 100x28x78 [mm]

- One fully automatic band saw (Nicotec: SCH-25FA)

-

This machine tool cuts metal and the like by rotating a band-shaped saw blade at high speed.

Used for cutting cylindrical materials and thick plates.

Automatic band saw ideal for cutting many items of the same type (size).Specifications Cutting ability: cylindrical material φ250 [mm], square material W300xH250 [mm]

Saw blade dimensions: 27x0.9x3505 [mm]

Saw blade continuously variable transmission

Equipped with quick approach function

Equipped with a saw blade break detector

- One 3D measuring device (Mitsutoyo: QM-Measure353)

- One electric injection molding machine (FANUC: ROBOSHOT S-2000i30B)

-

It is a high productivity machine tool that can produce various resin molded parts for optics, medical care, automobiles, etc.

Specifications Maximum mold clamping force: 300 [kN]

Mold thickness (max-min): 300-150 [mm]

Mold opening/closing stroke: 230 [mm]

Screw diameter: 22 [mm]

Maximum injection volume: 29 [cm3]

Maximum injection pressure: 180 [MPa]

Injection speed: 525 [mm/s]

Welding factory

- 1 laser processing machine (Amada: Quattro AF1000E)

-

This is a processing machine that can perform metal cutting such as drilling in a non-contact, high-speed, high-precision manner using laser light.

Precision parts processing such as cutting and drilling of sheet metal and drilling of square pipes (up to 100 mm) is possible.

Specifications Maximum machining range (XxYxZ): 1250x1250x100 [mm]

Machining speed: 0-10 [m/min]

Rapid traverse speed (X_Y_Z): 30_30_15 [m/min]

Maximum machined plate thickness :

Soft iron (oxygen cutting) 6.0 [mm]

Stainless steel plate (oxygen cutting) 4.0 [mm]

Stainless steel plate (nitrogen cutting) 2.0 [mm]

Aluminum plate 1.0 [mm]

Maximum output: 1 [kW]

Repeated positioning accuracy: ± 0.01 [mm]

- 1 MIG welding machine (manufactured by Daihen: DIGITAL AC WAVE 200A)

- One TIG welding machine (DAIHEN: INVERTER ELECON 300P)

- CO2/MAG welding machine (DAIHEN: INVERTER AUTO 350A) 1

- CO2/MIG/MAG welding machine (DAIHEN: INVERTER DP350) 1 unit

- CO2/MAG Welding Machine (DAIHEN: TURBO PULSE 350) 1

- 1 unit for both arc welding and CO2welding (manufactured by Daihen: DYNA AUTO XD500G)

- 1 arc welding machine (Hitachi: Super Pair 200RP3)

- 1 air plasma cutting machine (Daihen: VRCM-55)

- One vertical drilling machine (YUD=540, manufactured by Yoshida Tekkosho)

- Used for drilling large diameters that cannot be mounted on a tabletop drilling machine, or for drilling large materials.

- Table drilling machine (Hitachi Koki: BD-3602) (Yoshida Iron Works: YBD-360) 1 each

- Metal saw cutting machine (Hitachi: CB-13) x 1

- 1 high-speed cutting machine (SHOWA: HCW-16)

Foundry/multipurpose training room

- High frequency induction melting furnace (Kitashiba Electric) 1 unit

-

This machine can melt metals such as cast iron and aluminum.

Specifications Maximum receiving capacity: 50 [kWh]

Frequency: 1000 [Hz]

Rated power: For melting aluminum alloy 50 [kW] For melting cast iron 100 [kW]

Melting amount: Aluminum alloy 20 [kg] Cast iron 50 [kg]

- Molding machine (M-200, manufactured by Ikeda Seisakusho) (A-200, manufactured by Togiken Co., Ltd.) One for each

- One shot blast machine (Shinto Kogyo: SLB-1)

- 1 cartridge filter type dust collector (manufactured by Daihen: FB-900)

- One sand blender (Tokyo Giken Co., Ltd .: ASB)

- 1 desktop thread saw (Ryobi: TF-5400)

- 2 desktop band saws (Ryobi: TBS-80)

Sheet metal factory/Sheet metal finishing factory

- Sketcher (Komatsu Seisakusho: SHS6-205) x 1

- It can cut materials up to 6 [6] thick and 2,000 [㎜] wide.

- 1 bending machine (Amada: RG-M2 3512)

-

Hydraulic bending machine equipped with NC device that automatically controls with simple input operation

Specifications Pressing capacity: 350 [kN]

Bending length: 1,250 [mm]

Quick closing speed: 46 [mm/s]

Bending speed: 8 [mm/s]

Opening speed: 40 [mm/s]

Workable plate thickness: Iron plate 6 [mm] (up to 720 [mm])

Number of NC control axes: 2 axes (D axis {vertical}, L axis) {Back gauge})

- Spot welding machine (DAIHEN: SLAJ35-601) 1 unit

-

It is a welding machine that sandwiches two metal plates between electrodes, applies a large current while applying strong pressure, and uses heat generated by the electrical resistance of the metal.

Specifications Maximum welding current: 14,400 [A]

Thickness that can be welded: Iron plate 0.3-7.0 [mm] SUS plate 0.3-4.0 [mm]

Aluminum and copper cannot be welded

- One resiner (Hitachi Koki: BGH-100) (Shimomura Denyusha Seisakusho: DBG-4) one each

- 1 TIG welding machine (made by Daiden: SR-D180F)

- 1 MIG welding machine (DAIHEN: INVERTER DIGITAL ELECON DA300P)

- One hydraulic press (Osaka Jack: HPD-50)

- 5 desktop drilling machines (YBD-360, manufactured by Yoshida Tekkosho)

- 2 table drilling machines (Hitachi Koki: B13SH)

- 1 sample cutter (Malto: MC-122)

-

Machine used for cutting various materials.

Specifications Cutting wheel: (WA, GC) diameter 200 [mm]

Power supply: 3 phase 400 [W] with automatic feed function

- Electric furnace (Yamato Scientific: FO 810) 1

- One high-speed cutting machine (Hitachi Koki: CC14SA)

Department in charge: Technology Creation Department